In new construction often this product is sprayed between joists or studs allowed to expand and cure and then.

Polyurethane vs polyisocyanurate spray foam insulation.

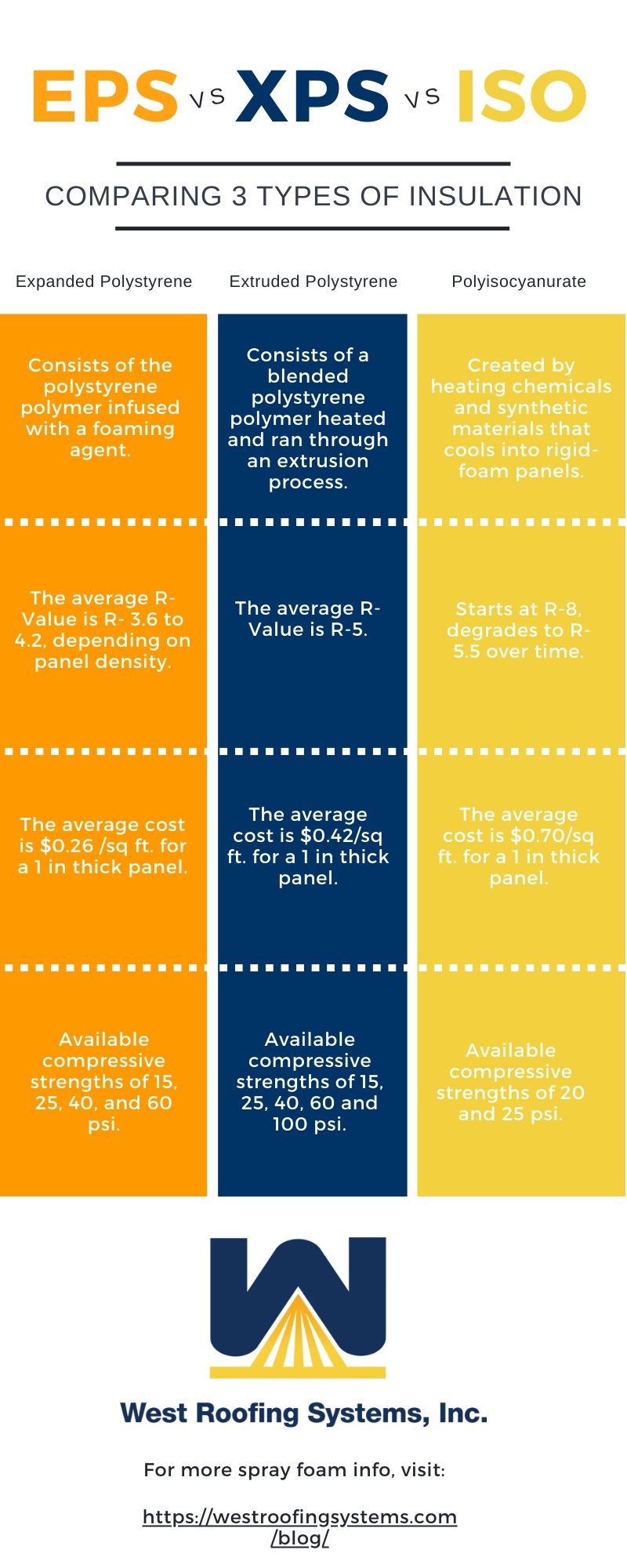

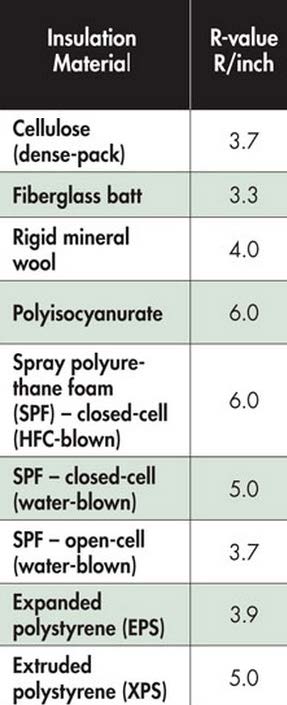

Polyisocyanurate s typical r value for the same 1 of material is approximately 6 0.

When laminated into a 1 thick panel with standard 1 8 substrates and aluminum skins the polystyrene panel yields a total r value of approximately 4 7 while the polyisocyanurate panel will achieve an r value of 6 4.

Polyurethane spray closed cell foam insulation.

Insulation or other building material 9.

Polyisocyanurate polyurethane foam insulation r values.

It s because they are some of the most efficient thermal insulating products for buildings.

Examples include 1 polyisocyanurate roof insulation and spray polyurethane foam roofing systems directly applied to steel roof decks 2 some.

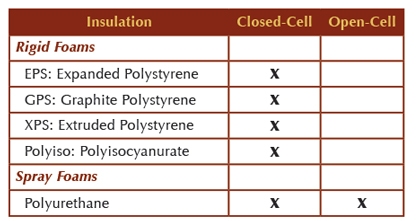

Available spray foam types include cementitious phenolic polyisocyanurate polyiso and polyurethane.

Some polyurethane and polyisocyanurate foam insulations and systems have earned various building code acceptances for use without a thermal barrier as a result of this large scale fire testing.

The spray formula of icynene foam insulation has an r value of r 3 6 per inch.

Thanks to thanks to andrew cole for correcting our data on this product.

R values of icynene foam insulation polyurethane foam insulation.

It is the processing that ensures consistency in the foam core and adhesion to the steel facings and that will result in a premium composite product.

At a quick glance polyisocyanurate or rigid polyiso foam known as pir appears to be the next generation development of the classic polyurethane rigid foam or pur in short.

Polyisocyanurate foam insulation panels come with a layer of foil on each side to keep the gases in so there is the potential to solve a bit of a growing problem in wall assembly durability.

Foil is a vapour barrier and a very good one at that it fact it stops even more moisture than the normal.

Additional considerations with polyisocyanurate.

Instead minimum physical properties should be listed as performance specifications for the foam core of imps.

Polyurethane foam including foam rubber is sometimes made using small amounts of blowing agents to give less dense foam better cushioning energy absorption or thermal insulation.

Buildings why are plastic based products such as rigid polyurethane foam pur spray polyurethane foam and polyisocyanurate foam insulation pir or polyiso at the center of the discussion.

Assessing thermal performance despite claims that certain types of insulation perform better than others an ongoing study by building science corp.

In comparison a typical 1.

Make the assumption that polyurethane or polyisocyanurate foam is superior.

Aging effects comments.

The poured in formula for icynene foam insulation has an r value of r 4 per inch.

Bsc in westford mass suggests that all insulation delivers the same performance under.